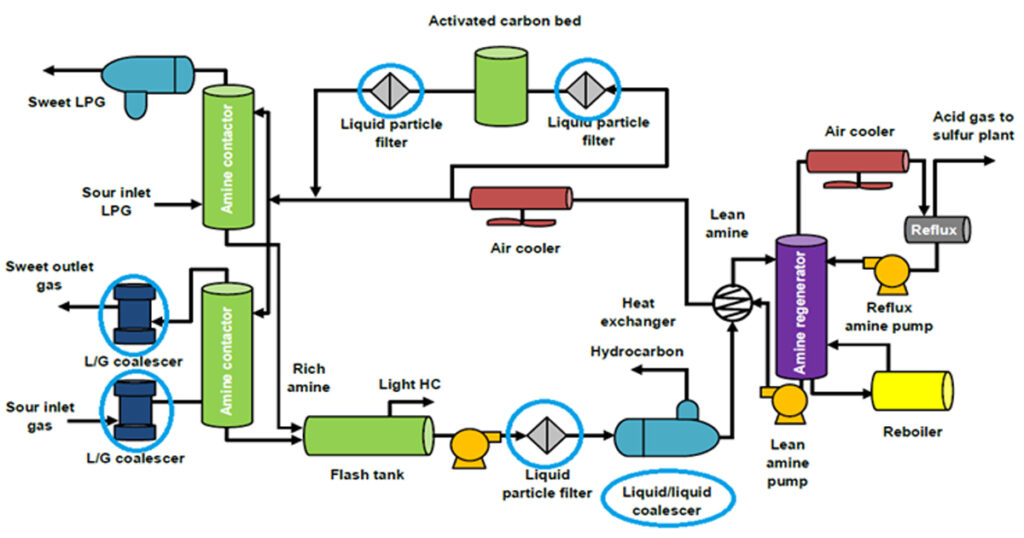

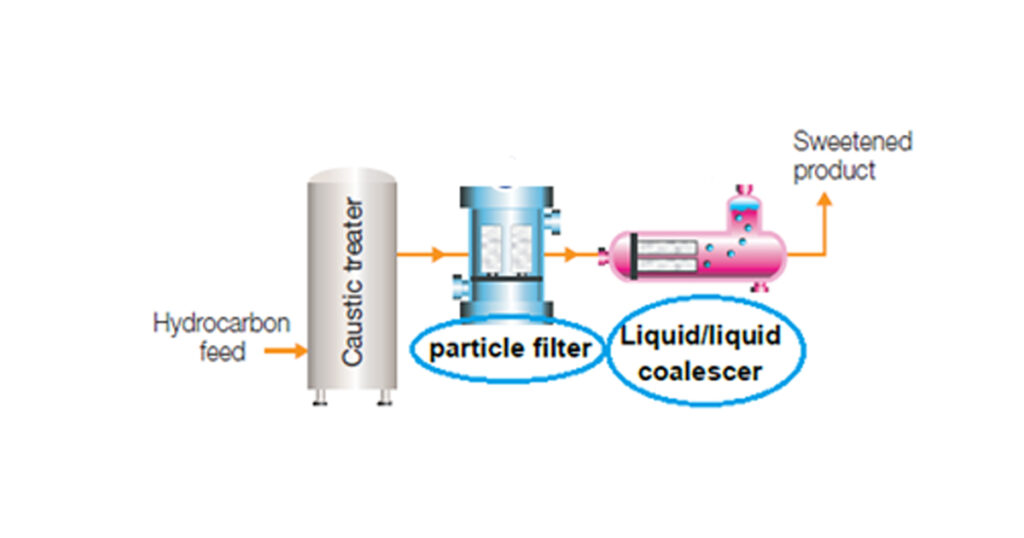

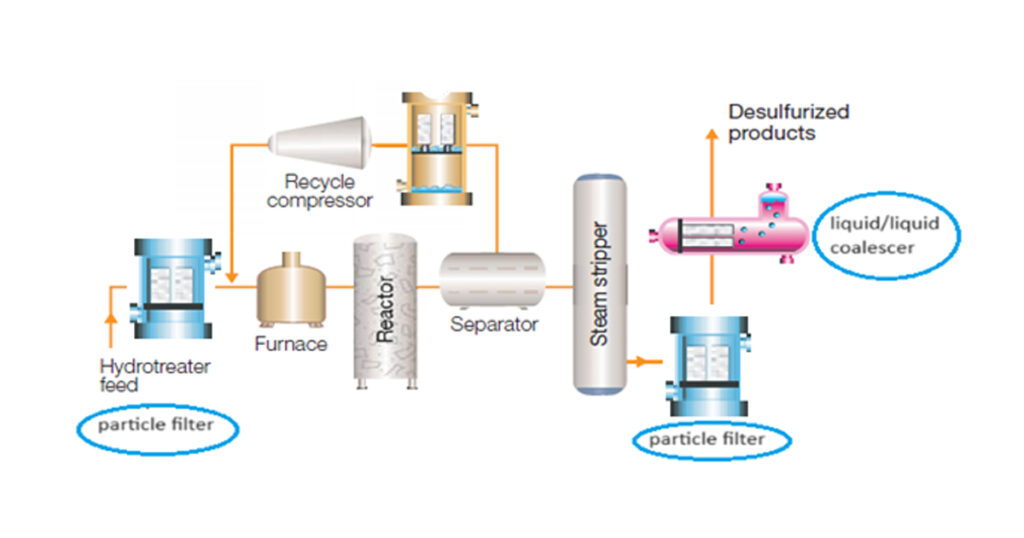

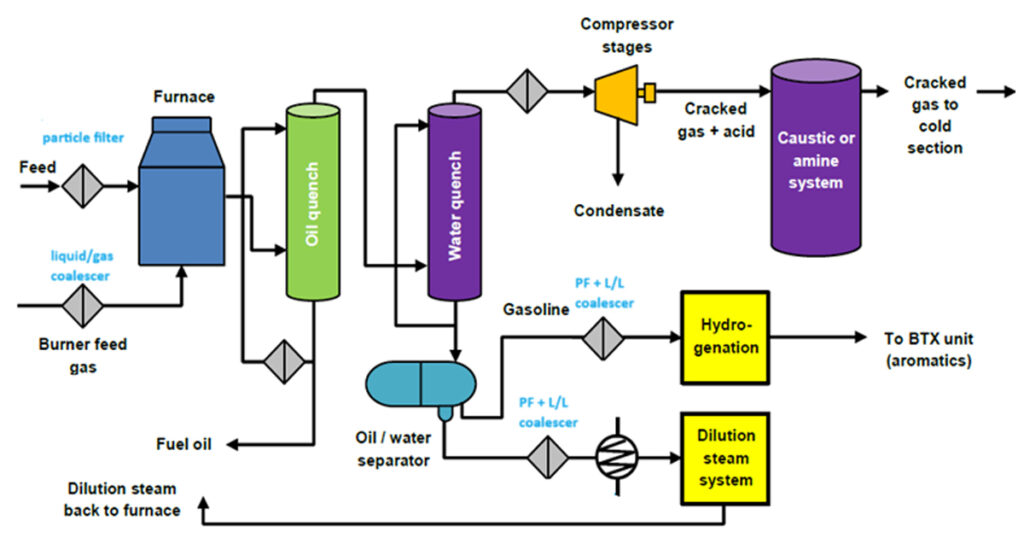

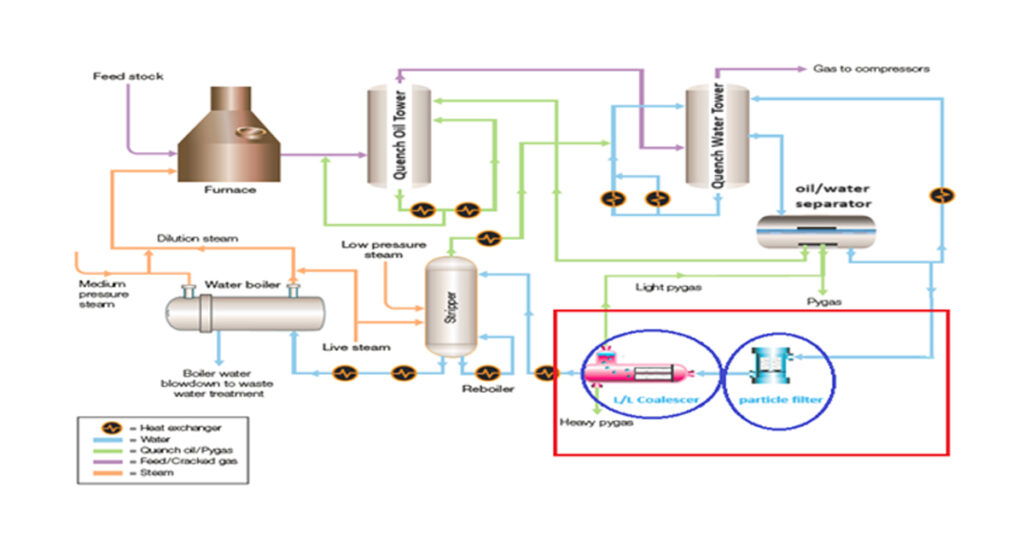

Filtration in refineries Filtration plays a significant role in improving the fluid quality of the process fluids and final desulfurized product by protecting the downstream pump, heat exchanger, heater, compressors, and the fixed-bed catalyst reactor.

Preloader Close