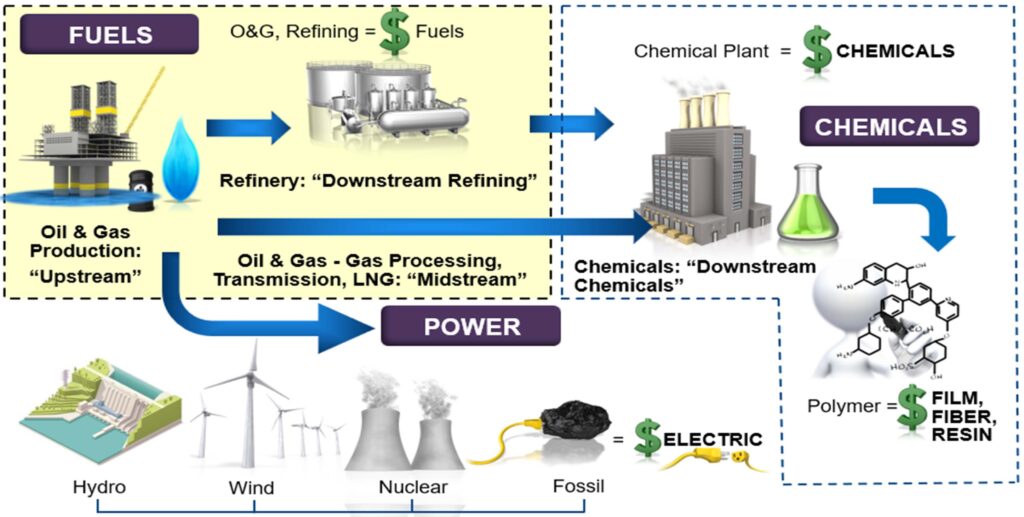

In the Oil & Gas Industry, an efficient filtration/separation system is critical to the reliability and performance of the physical assets that process petroleum products. Optimizing the reliability of these filtration systems is essential in maximizing your operational performance.

Preloader Close